Fixed bench automatic cutting machine

The only versatile, flexible, modular and convertible cutting robot!

»Maximum height of compressed fabric: 3 cm and 6 cm

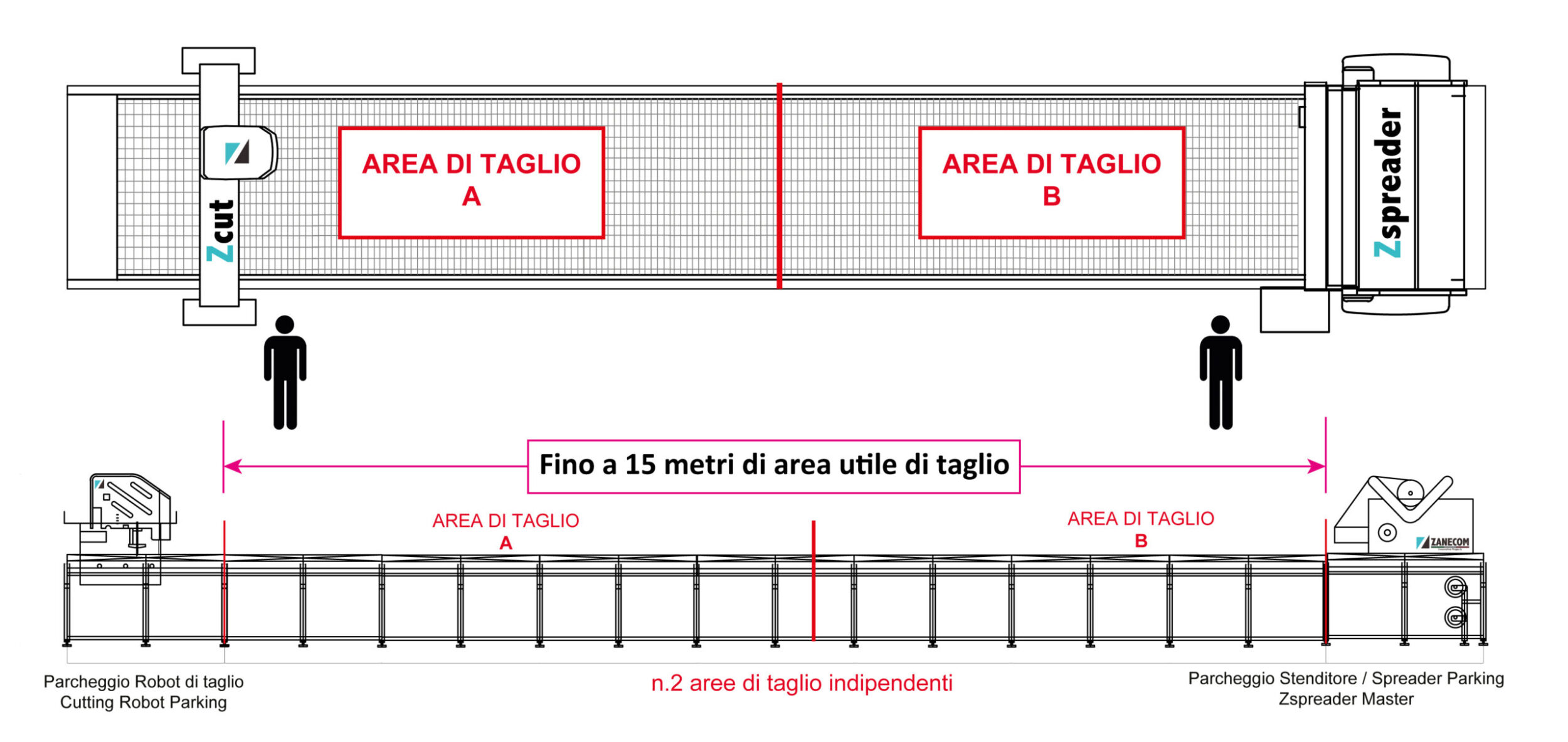

»Cutting area width: from 160 to 240 cm

MODULAR

The modules of the cutting table adapt to the load of the company's production: Zcut Universal grows together with the customer, adapting to their needs.

FLEXIBLE

Light weight, small footprint, completely demountable to be installed in different production spaces, also divisible into two independent work areas for total flexibility.

VERSATILE

Suitable for both small companies and small productions, and for large companies that think of their more efficient and automated prototype development department.

And by also applying the spreader you have a complete and automated cutting room at an incomparable cost.

MODELS

- Zcut Minerva T3 (3 cm compressed)

- Zcut Minerva T6 (6 cm compressed)

FUNCTIONS and FEATURES

»Smart All-In-One Touch Computer

»Cutting software compatible with all CAD systems

»Operating system that monitors all parameters on the screen

»Software interface available in various languages

»The files can be checked on the screen before the cutting process

»Possibility of changing the cutting sequence for better optimization

»Selection of the pieces that are not to be cut before the cutting process

»Detection of the angle of the tissue by laser and cutting with the same transversal angle

»Possibility to manage and convert all types of notches (normal, V and T)

»When the marked does not fit the width of the fabric, it is possible to change the scale of the pieces

»The operator can change the length of the cut

»Quick and easy saving of cutting profiles for quick retrieval and accelerating future cuts

»The blade may not cut adjacent lines twice (no overcuts)

»Blade monitoring system to control abrasion and stop cutting automatically

»Optimization and possibility to change the corner radius of the pieces

»Resume cutting after pausing or stopping the machine

»Management of speed ramps in low to the type of fabric to increase cutting efficiency

»Different cutting options (" butterfly ", clockwise or anti-clockwise)

- CHANGEABLE AND AUTOMATICALLY MANAGED ASPIRATION PARAMETERS

Average consumption 7-9 kW (* depends on the number of sheets and the type of machine) - "VORTEX" BLADE COOLING SYSTEM

- AUTOMATIC AND PARAMETERIZABLE BLADE SHARPENING SYSTEM

- COVER "CURTAIN" TO IMPROVE THE EFFICIENCY OF THE SUCTION

- 4 AXIS MOVEMENT CONTROL (X, Y, Z, C)

- AXES CONTROLLED BY AC SERVO MOTORS

- LONG-LASTING BRUSHES with EASY LOCK system (Plug & Play)

- EASY TO USE CONTROL PANEL TO MANAGE THE MOST COMMON FUNCTIONS OF THE MACHINE

- POSSIBILITY TO CREATE CUSTOMIZED PROFILES

- AUTOMATIC HOT DRILL WITH ADJUSTABLE DIGITAL TEMPERATURE

SUCTION SYSTEM

»Material firmly in place during the cutting process

»Minimum energy consumption controlled by inverter and vacuum gauge

»Parametric stepless adjustable vacuum

»Vacuum turbine filter

»Integrated silencer for exhaust

PLASTIC COVER

»Avoid suction losses

»Automatic winder and unwinder device

AUTOMATIC HOT DRILL WITH ADJUSTABLE DIGITAL TEMPERATURE

(Double drill optional)

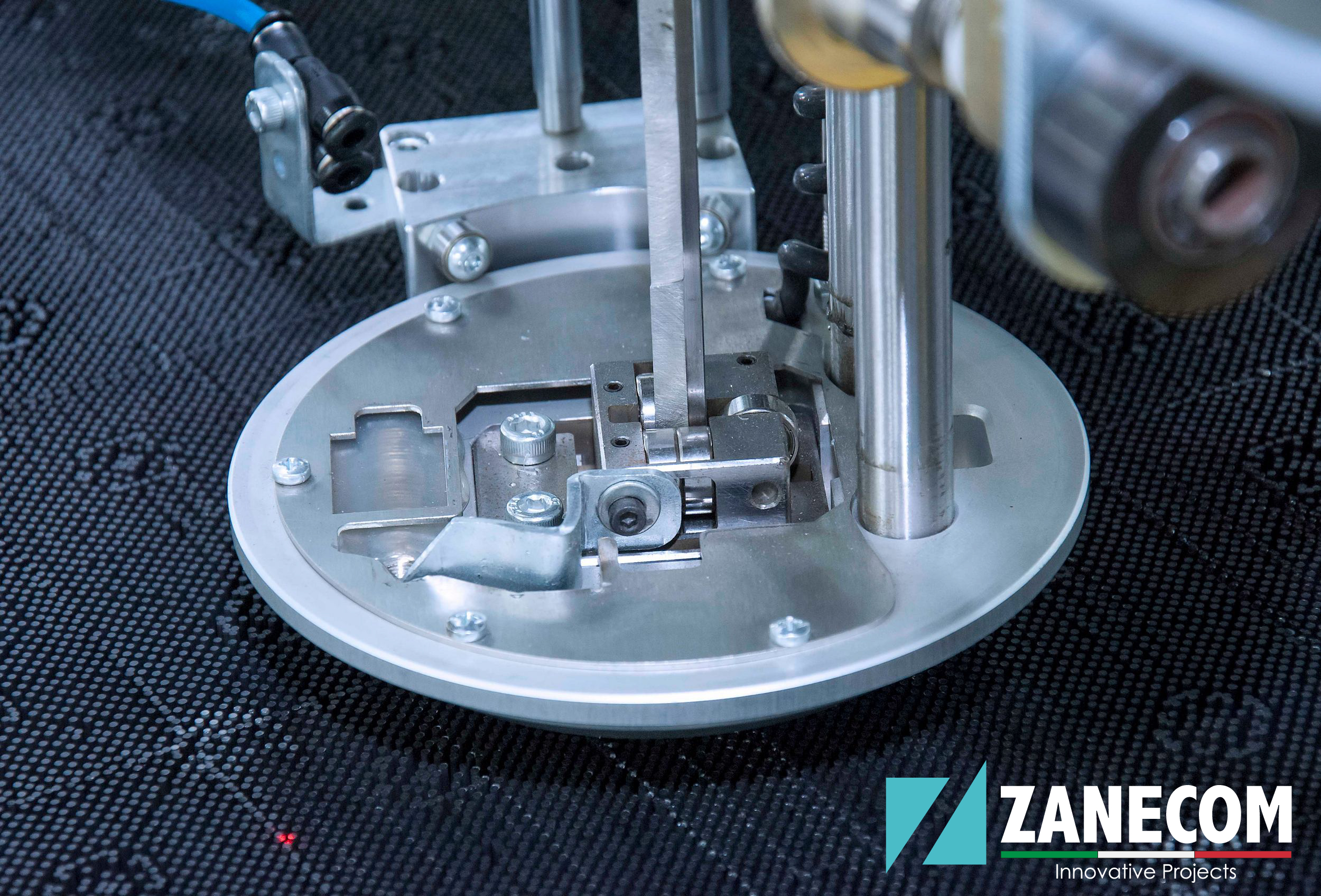

ACCURATE HARDWARE

»Assembly of quality components purchased from reputable suppliers

»Motion controller, 4 axes (X, Y, Z axis)

»Brushless AC controlled motors

»X and Y axes guided by linear modules